ERNST

Twin X Automatic Durometer

Twin X Automatic Durometer

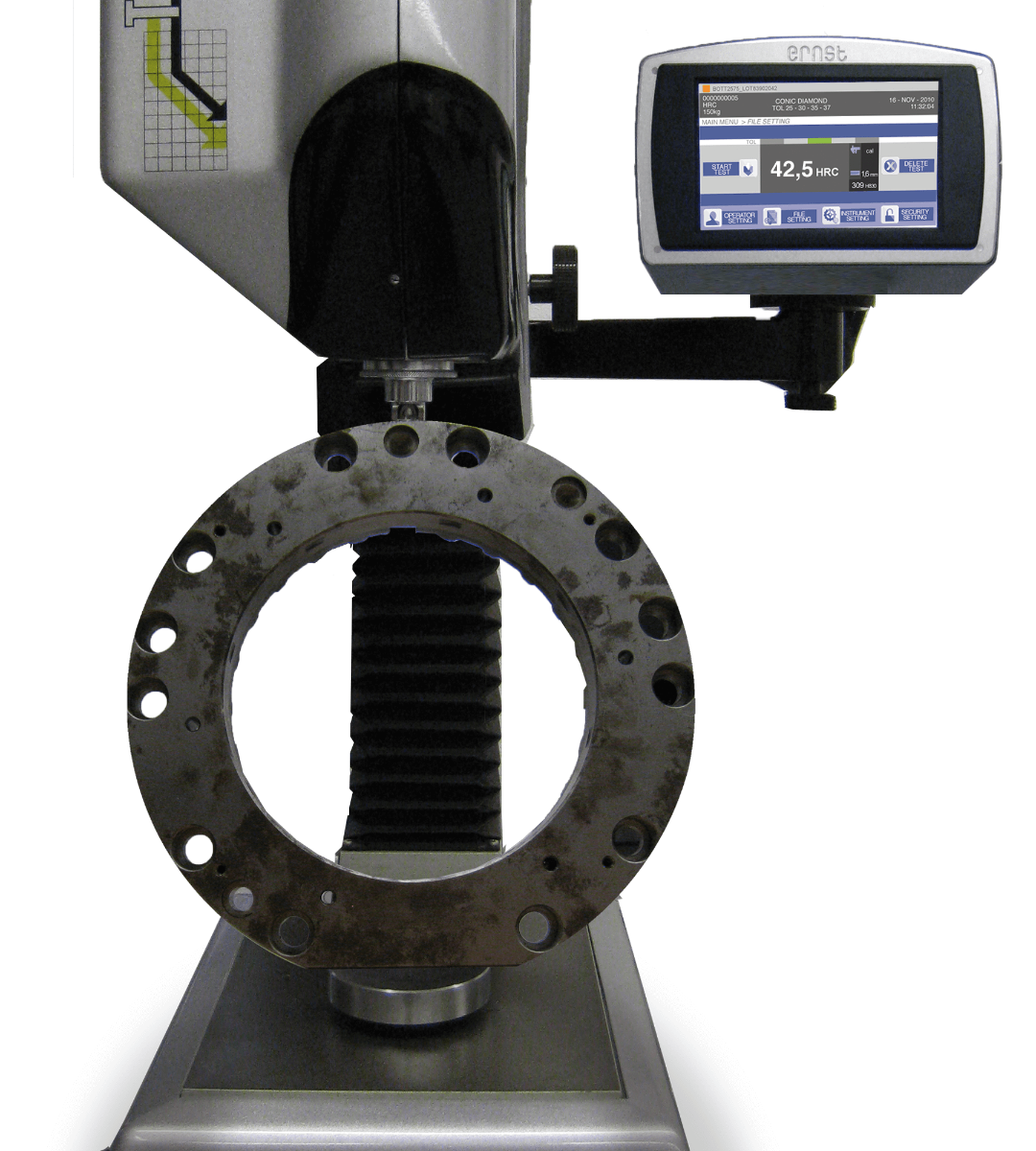

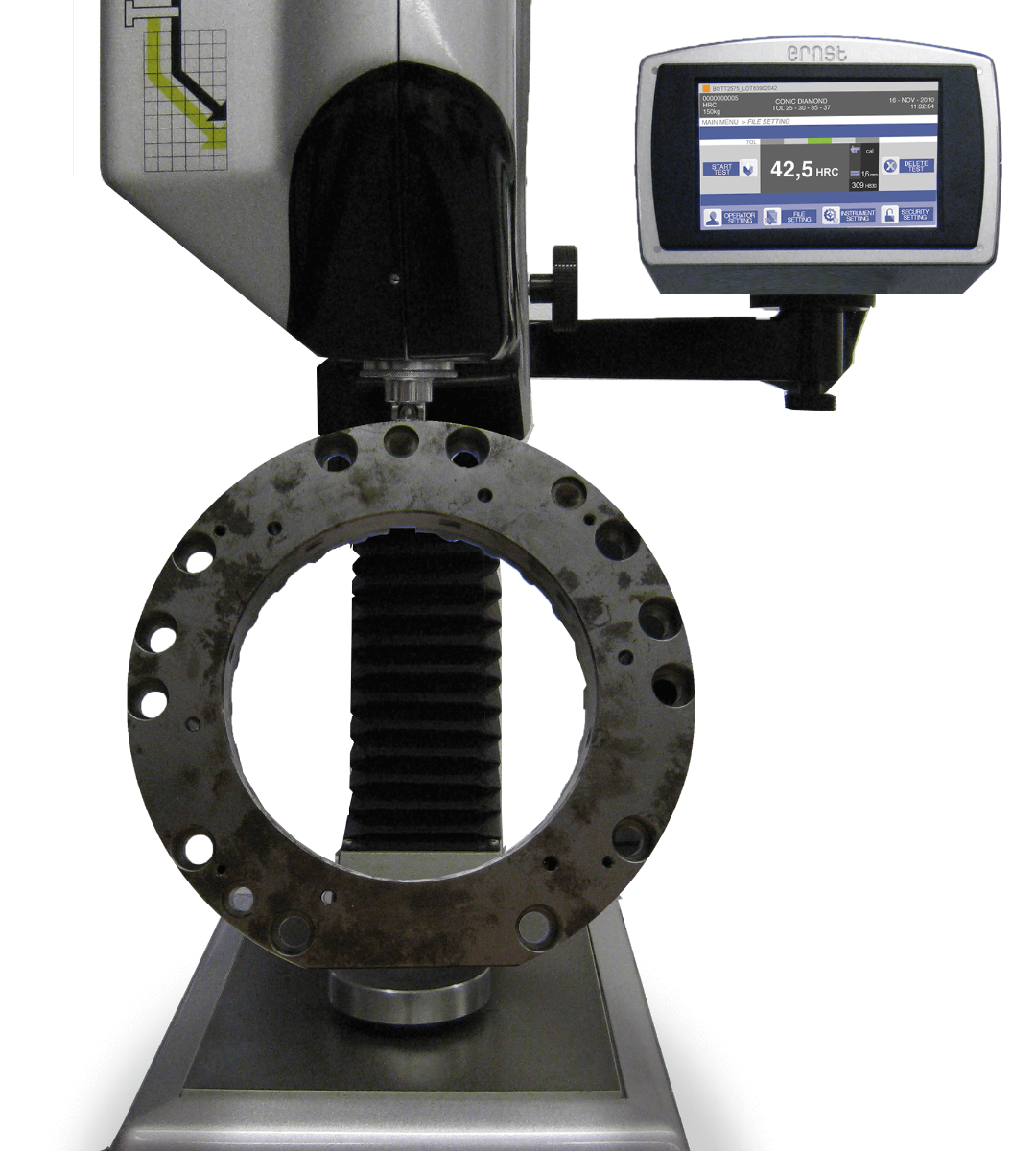

The TWIN-X is a fully automated Rockwell hardness tester designed for seamless performance in Rockwell and Super Rockwell hardness testing. Capable of handling large parts up to 420 mm in height in its standard configuration, this advanced hardness tester is a game changer for efficiency and productivity.

Featuring an innovative spring system that outperforms traditional load cell systems, TWIN-X reduces each test cycle by up to 10 seconds. This translates into significant productivity gains, saving 12 minutes per hour, or nearly two hours per workday.

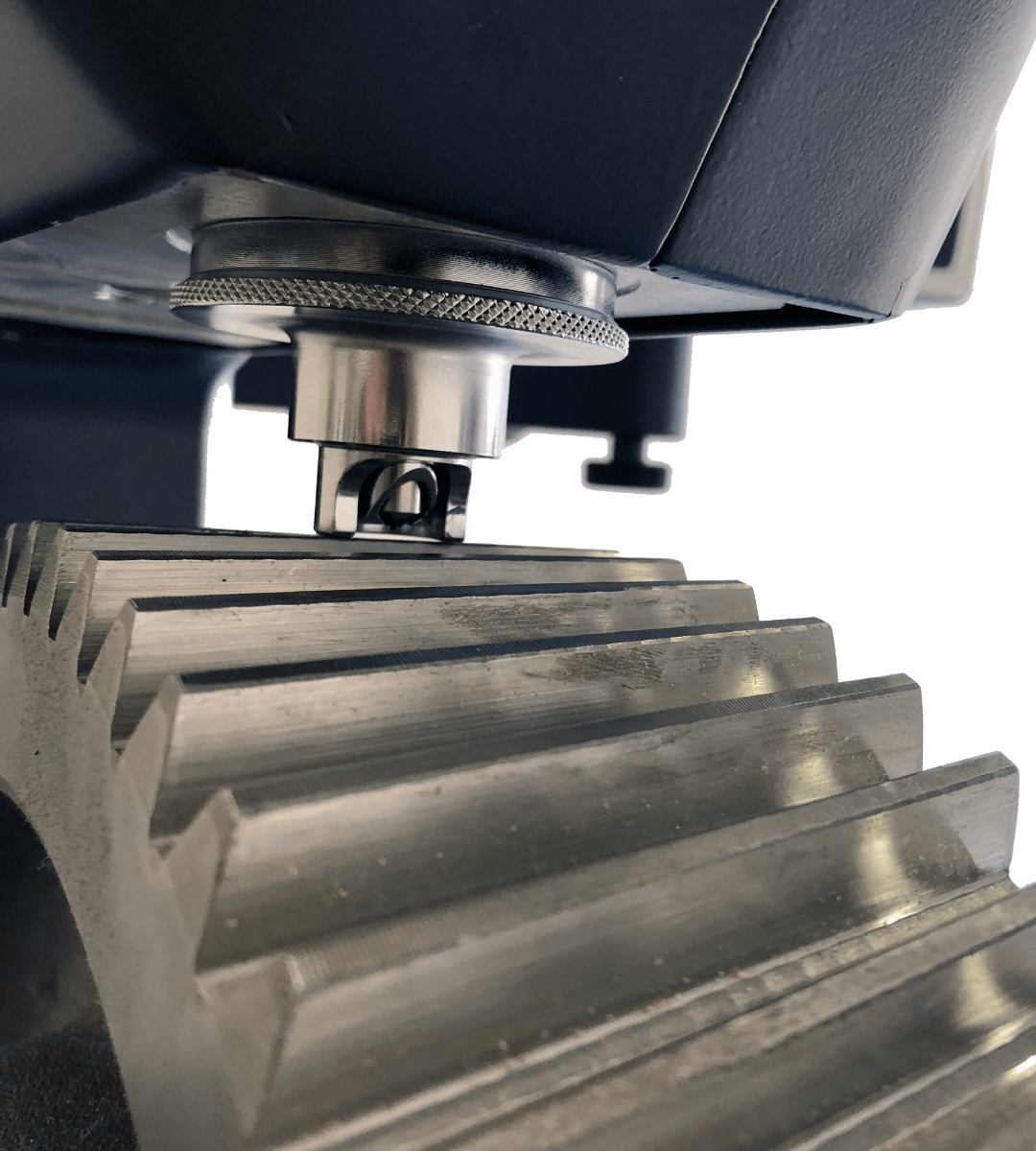

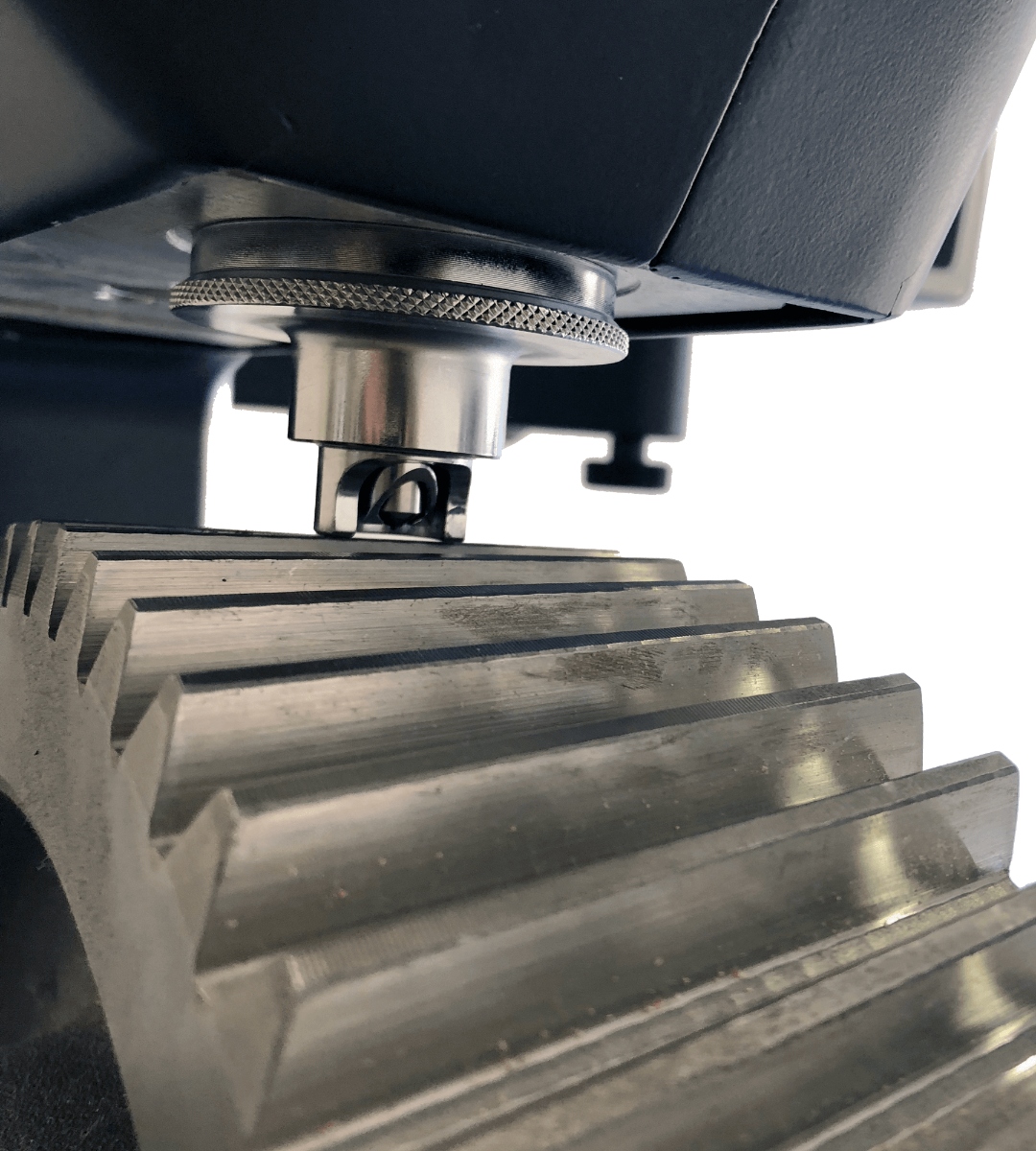

Designed to meet a variety of hardness testing needs, the TWIN-X boasts an impressive indenter stroke of up to 45 mm, allowing testing on varying thicknesses without manual adjustments. Its clamping shield facilitates accurate testing on protruding workpieces without external support.

With a fully automated vertical axis motion and load application system, TWIN-X simplifies the entire hardness testing process. Its integrated safety device retracts the indenter to protect against misaligned workpieces or foreign bodies.

Specially designed for non-standard applications, TWIN-X offers high flexibility for custom configurations. The screw unit can be removed to accommodate larger parts such as molds and castings, and a specialized version with a +500 mm support is available for testing parts up to 950 mm high. In addition, the removable measuring head integrates seamlessly into production line control systems, improving versatility and efficiency.

Key benefits of TWIN-X include increased productivity, versatile application, and custom configurability for specialized tasks.

Share