ERNST

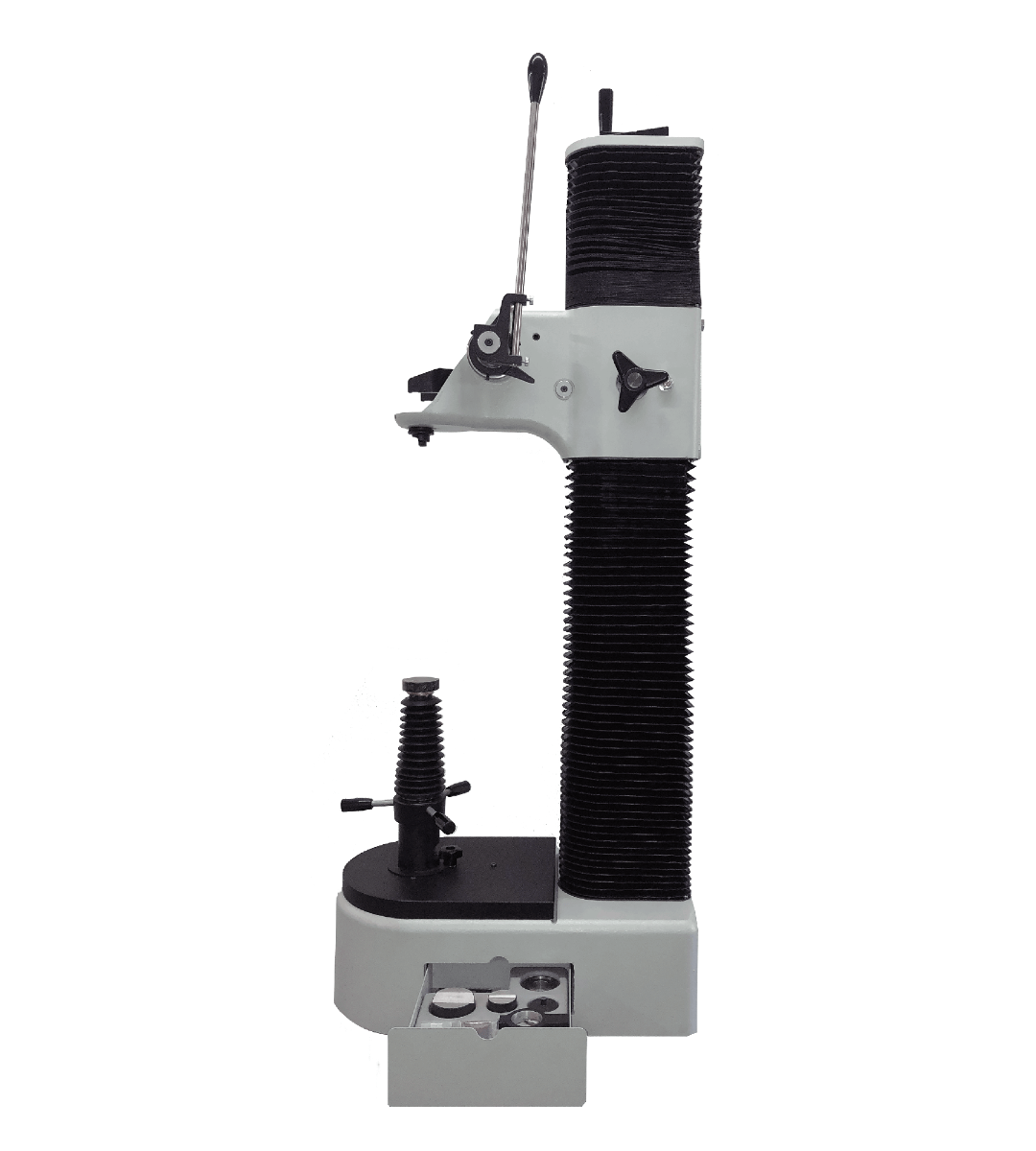

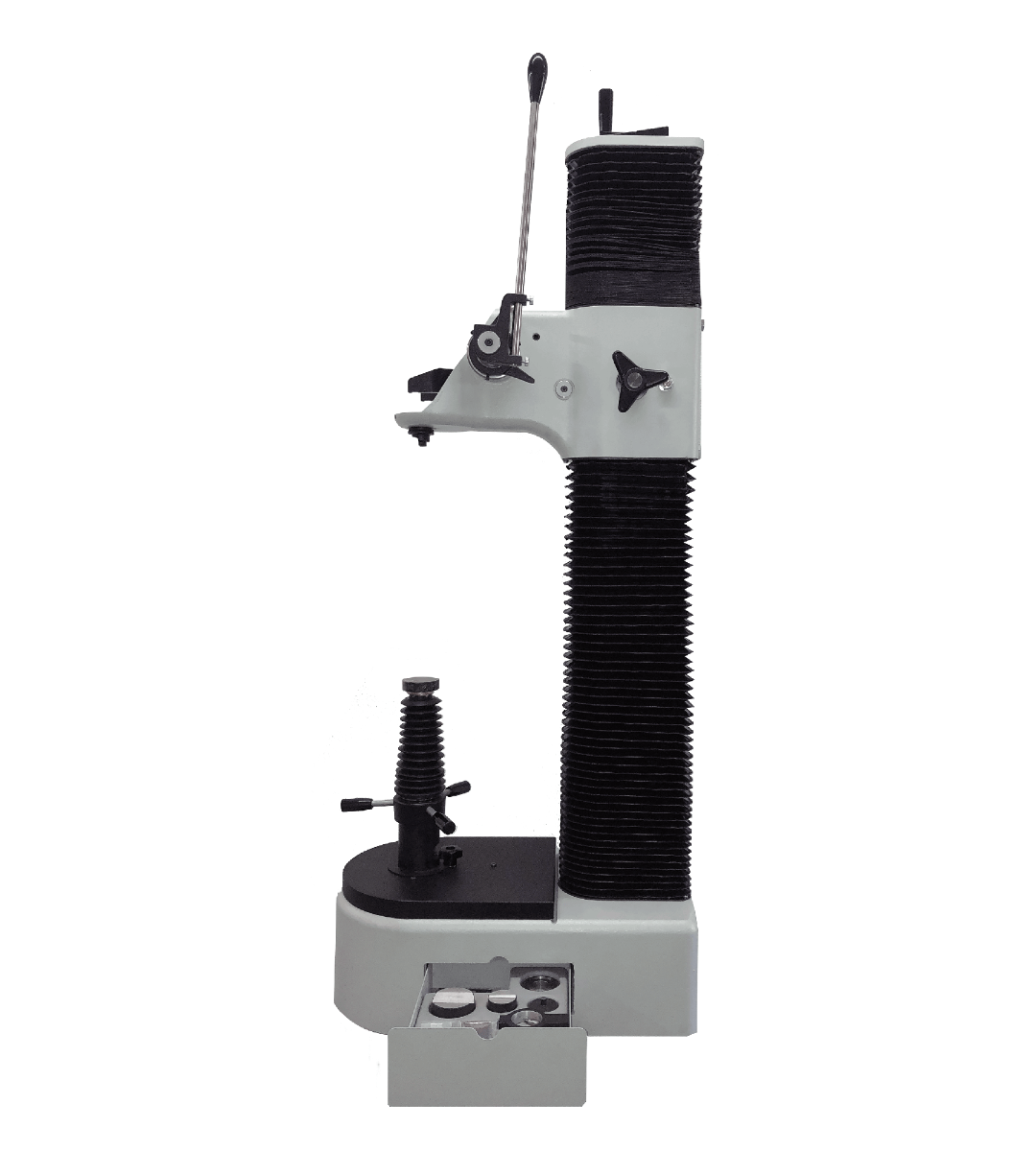

AT250 Benchtop Hardness Tester

AT250 Benchtop Hardness Tester

Cisam-Ernst Rockwell Hardness Testers: Precision, Reliability and Innovation with AT250 D

In the landscape of materials engineering, Rockwell hardness testers are an essential tool for measuring the hardness of materials. Cisam-Ernst, with its AT250 D model, embodies the evolution of this tradition, offering a cutting-edge solution that combines the precision and speed of traditional Rockwell hardness testers with electronic innovation for processing test data.

AT250 D Durometer Key Features:

- Test Speed: The Rockwell principle allows tests to be performed in just 2 seconds, ensuring improved productivity.

- Spring Loading System: It provides reliable testing that complies with international standards, ensuring measurements that are insensitive to material sagging and deflection.

- Versatility and Precision: Available in normal and superficial Rockwell versions, AT250 D performs accurate tests on different materials in compliance with UNI, ISO, DIN and ASTM standards.

- Robustness and Adaptability: Resistant to the most difficult environments, thanks to the spring loading system, it maintains performance even in extreme conditions of temperature, dust and humidity.

- Advanced Communication Technology: Thanks to the wide choice of interfaces, AT250 D facilitates the sharing of measurement data, in line with the principles of Industry 4.0.

Benefits Offered by the AT250 D:

- The test speed of just 2 seconds improves the efficiency of the quality control process, allowing companies to handle a greater volume of tests without compromising accuracy.

- The spring loading system ensures highly reliable measurement results that comply with international standards, avoiding errors and ensuring that products comply with industry requirements.

- The versatility and precision offered by the durometer allow for the evaluation of a wide range of materials, ensuring compliance with UNI, ISO, DIN and ASTM standards.

- The robustness and adaptability of the device allow it to be used in a wide range of environments, ensuring the continuity of the production process even in the most difficult conditions.

- The availability of interfaces allows easy integration of the hardness tester with digital systems, improving data management and information sharing within the company, offering a competitive advantage.

Evolution of the AT130 Model: The AT250 D line of hardness testers represents the evolution of the well-known AT130 model, a device sold in thousands of units worldwide since the 1970s. It brought significant innovation to the industry thanks to the ability to quickly measure the hardness of large components, with a system insensitive to sagging and flexure.

Commitment to Quality and Durability: Cisam-Ernst guarantees the accuracy, reliability and solidity of its Rockwell hardness testers through constant commitment to design. Each device is built to offer high performance over time, even in the most difficult environmental conditions.

Conclusion: The AT250 D hardness tester represents the perfect synthesis between the tradition of Rockwell hardness testers and technological innovation. It is an essential instrument for anyone looking for a reliable and precise solution for material hardness testing.

Share