REMET

THINNING OPERATIONS

THINNING OPERATIONS

REAR-CUT

The sample glued on the slide, after the appropriate cleaning of the excess resin and the appropriate marking, must be subjected to the back-cutting operation. This operation can be carried out with petrographic cutters or with MICROMET cutters equipped with the appropriate sample holder with vacuum device. Thanks to the micrometric movement of the sample holder it is possible to carry out the precise positioning of the slide with respect to the grinding wheel and obtain sections of the desired thickness.

After the back-cutting operation, the sample is thinned.

It can be performed using two systems:

- GRINDING on Micromet

- LAPPING with micrometric drum on polishers.

GRINDING

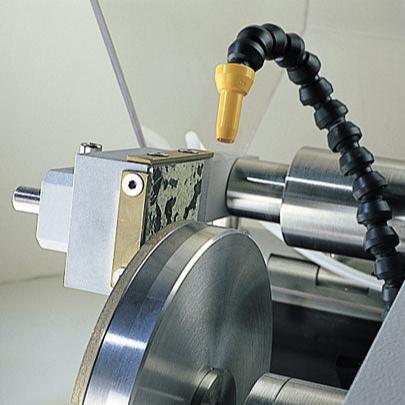

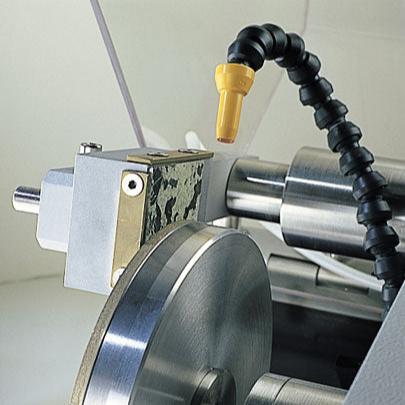

The MICROMET cutting machine equipped with the Grinding system allows you to perform the glass thinning operation with micrometric precision using a fine-grained diamond cup wheel.

The slide is fixed to the instrumentation by means of a vacuum slide holder. This component has been designed to accommodate all types of slides, even circular ones with a diameter of one inch. The structural characteristics of the equipment allow for vibration-free thinning and compliance with the most absolute plane-parallelism. The creation of thin sections with this technology is particularly simple and fast with a constant reference over time.

LAPPING

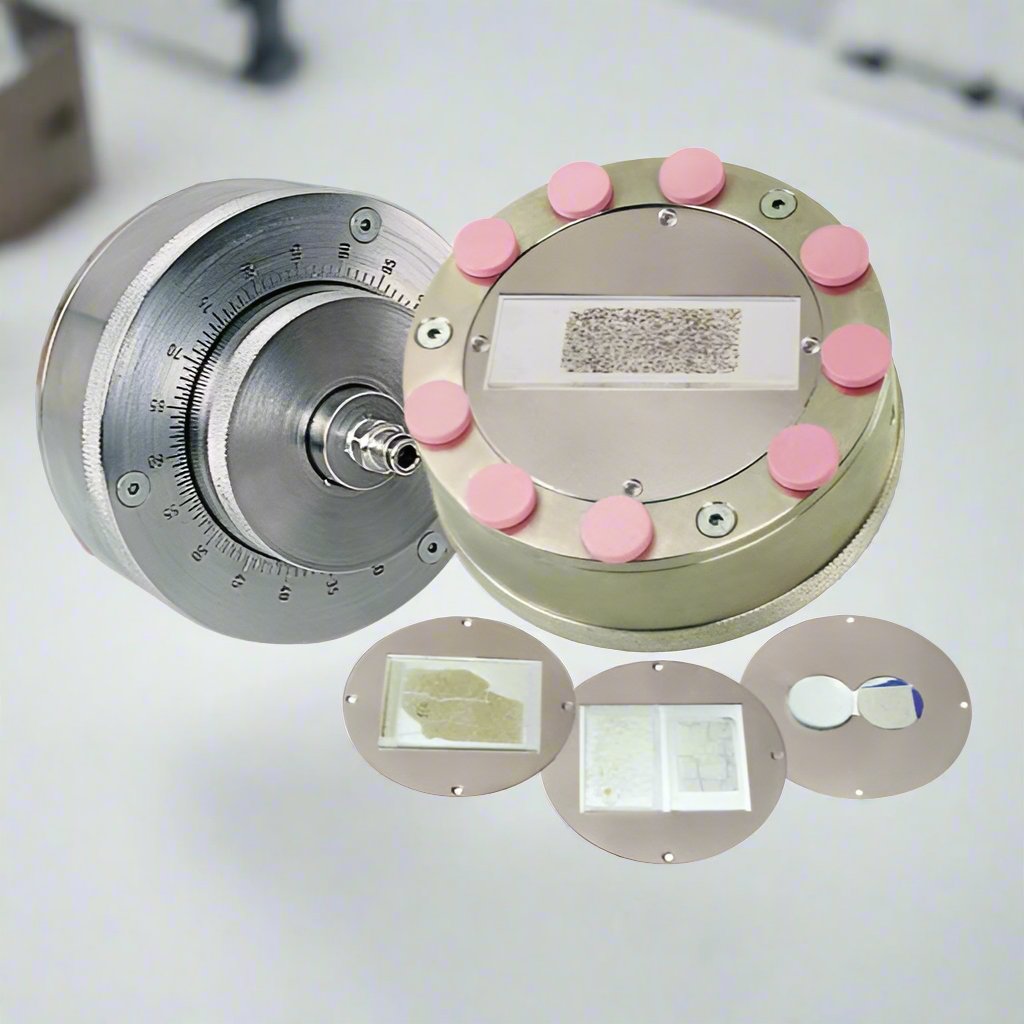

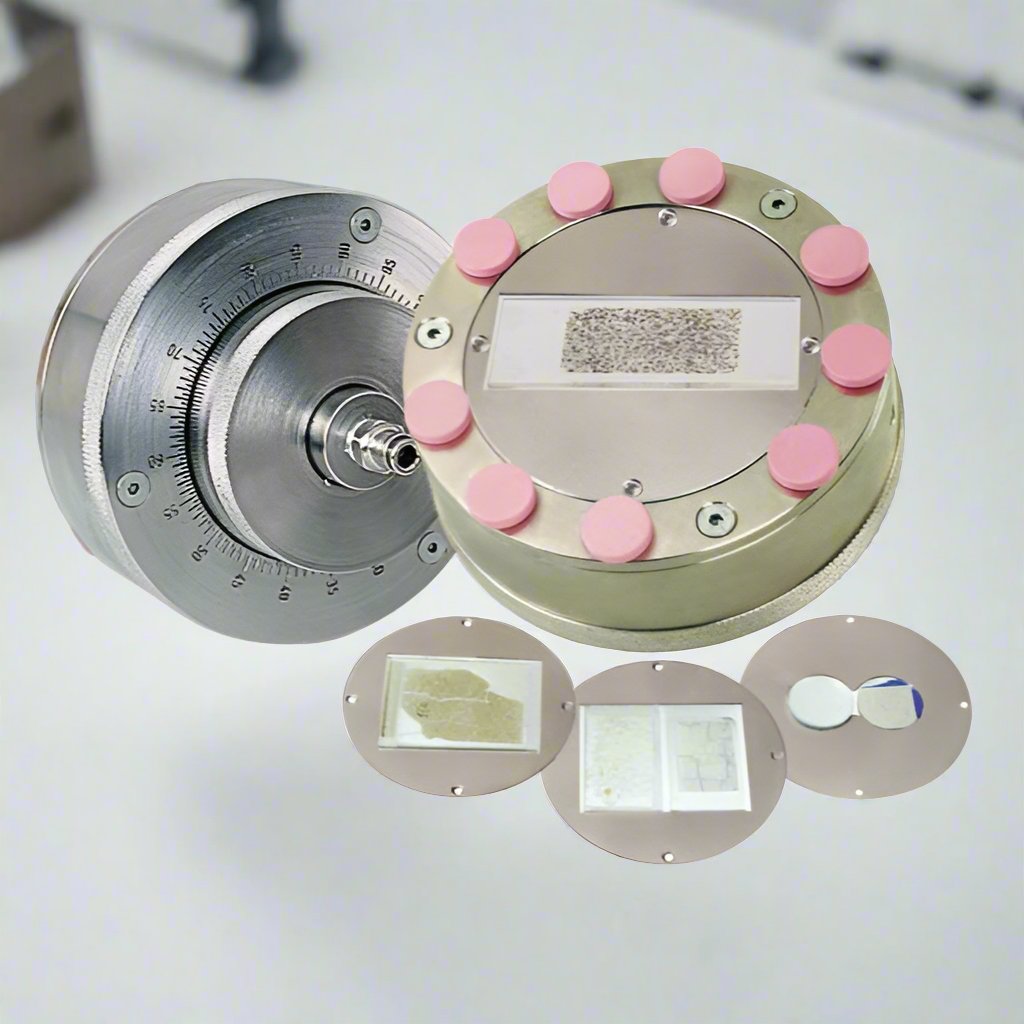

MICROMETRIC DRUM THINNING SYSTEM

The system consists of a polisher, a sample-holding drum with micrometric adjustment (the slide is gripped by vacuum), and a series of accessories. The thin section is created by lapping (or pre-polishing), using paper, cloth or abrasive powders. This system also allows the polishing of the slide.

The two preparation systems can be alternative or complementary. They have both been developed in order to offer the most suitable answer to the various needs. Both systems allow the calibration of the slide to the desired thickness.

Share